(This History of CAD/CAE Phases Timeline is the third blog in a 3 -part series. Here is Part 1, and Part 2)

Part 3: Product Development Phases

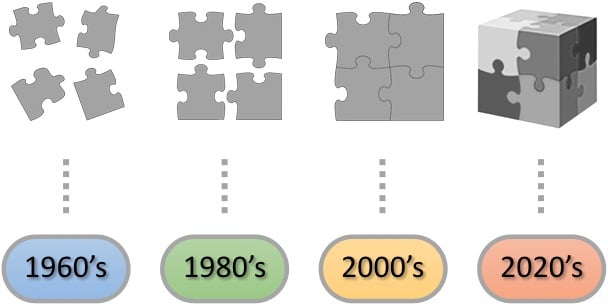

As we saw in the previous two articles, the Computer Aided Design/Engineering (CAD/CAE) industry offers a growing, and sometimes complicated, offering of tools and capabilities. But what it really comes down to is "What's the application?". In other words - in what phase of your product development lifecycle will you apply the tool. In addition, there can be great time and costs savings when you can leverage a tool across phases. As we will soon see, the major CAD/CAE brands are building "Platforms" of tools, that are used to help us develop better products faster.

By now, you are familiar with your CAD/CAE vendors' capabilities, but are you leveraging your design data across your entire CAD/CAE tool set? Are you using your CAD/CAE vendors' full portfolio in your entire product development lifecycle? Are you leveraging the industries latest capability for Data Analytics, and perhaps even Artificial Intelligence to develop better products faster? Perhaps the historical review can offer insight into where we are in the CAD/CAE landscape, and more importantly... where we are headed!

Interactive Data Viz

Once again, I decided to use the popular data visualization software, Tableau, to map this History of CAD/CAE Phases Timeline. In this map, however, I have color coded each path by the underlying product development phases. The grey horizontal lines separate the parent companies. For large companies, the parent company (most recognizable name) is in the middle. Scroll below, and use your mouse to hover over the nodes and learn more about each milestone in the amazingly dynamic industry of CAD/CAE.

A description of the different Product Development Phase Categories is listed below:

System - Once a product need has been established (for example, through strategy road maps, business development, and/or market research) the product itself must be laid out at the highest level. In this phase, questions being answered include "How will our product solve our customer's problem", "What combination of technologies could we use to develop a solution?", and "Which physics will be exercised during the operation of our product?". This phase becomes increasingly more important as the product itself becomes increasingly more complex.

Concept - Once a system has been designed, multiple concepts are brainstormed for how to package the system and the underlying subsystems. In this phase, CAD/CAE tools can provide high level mathematical representations (sometimes we say it has simplified "Degrees of Freedom", as opposed to full fidelity models further down in the proper Simulation phase), or simple graphical representations (i.e. "renderings") for the purposes of ruling out suboptimal ideas. From a budget/schedule standpoint, it is important to not spend too much time on unnecessary details in this phase.

Design - Once one (or perhaps several) concepts have been selected, the detailed design phase occurs. Here you will find the vast majority of 3D CAD tools, which are designed to help create detailed components and assemblies, as well as documenting their design for further tasks like test and manufacturing. This phase is where "the rubber meets the road", and the team will find out what fits together and what does not.

Simulation - In this phase, the design iterations are put to the test, virtually of course. Tools like FEA and CFD are used to predict performance and reliability. Failures are predicted, and designs are updated to reduce, delay, or even avoid potential failures altogether. This is our favorite "phase" of course, however our methodology leans more towards using Simulation as a tool in many phases. We find it is most effectively used in parallel with the Design phase, to help optimize the design.

Data Management - This is not necessarily a phase, but rather a set of tasks that need to occur in parallel with the product development lifecycle. Data management has become increasingly more important as more CAD/CAE tools are used, designs have more features, and systems become more complex, data becomes more difficult to manage. Effective Data Management occurs at the intersection of Information Technology, Infrastructure, Process Culture, and where applicable, Regulation.

Test - This phase typically occurs after a design prototype has been built. Tests are a way for design teams to emulate how a product will be used in the field by their customer. It validates design assumptions, and qualifies the performance and reliability. It is a critical phase which represents a critical milestone in any product development project.

Manufacturing - Product Development, for commercially applications, have one goal in mind: profitability. This occurs when the product can be manufactured at the right time, at the right quantities, by the right people, at the right cost. Tools in this phase focus on data measurement and time tracking, manufacturing automation, and cost reduction of raw materials and labor. Many of the latest tools can help measure and feed data back to the design team to check against the original design goals. These tools fall under some of the new technologies known as "Internet of Things", "Industry 4.0", and "Digital Twin".

Platform - This is not actually a phase, but rather just a catch all term for some of the parent companies (such as Altair, Autodesk, Dassault Systemes, and Siemens PLM) whose portfolio includes CAD/CAE tools across every phase of the product development lifecycle. There are huge opportunities at this level to leverage the entire portfolio ("full suite" or "full stack") of product development software. In general, the consolidation of the industry can be summed up by the fact that nowadays when we select a CAD/CAE tool, we are typically faced with selecting a certain brand's platform. If you are a CAD/CAE company, you are either trying to build a platform, or you will be absorbed in to one.

Data Viz Filtering: You can highlight a specific technology by clicking on it in the legend. You may also view just that particular technology by clicking on it and selecting "Keep Only". To Undo/Redo a filter, or to revert back to the original data set, click the corresponding buttons at the bottom of the data viz. View it in Full Screen Mode for the best graphics... Enjoy!

Credit

The data presented here is a mix of independent research and crowd sourcing. A big thank you goes out to the people on Linkedin who commented, shared, and connected with each other via the original Linkedin post. In addition, credit must go to David E. Weisberg who wrote an incredibly detailed book on the CAD industry called The Engineering Design Revolution, to Sebastian Fixson from Babson College who facilitated the original research as well as Olivier Catherin of Actinvision who offered some much needed guidance with the data preprocessing.

This map is a permanent work in process as the industry continues to grow (through startups and new technologies) and consolidate (through mergers and acquisitions). Therefore, if you see any inaccuracies, or want to notify us of an update, please drop us a line through the button below.

The story will continue to evolve, and this graphic will be kept up-to-date. To get notified when the next update occurs, sign up for our newsletter below!